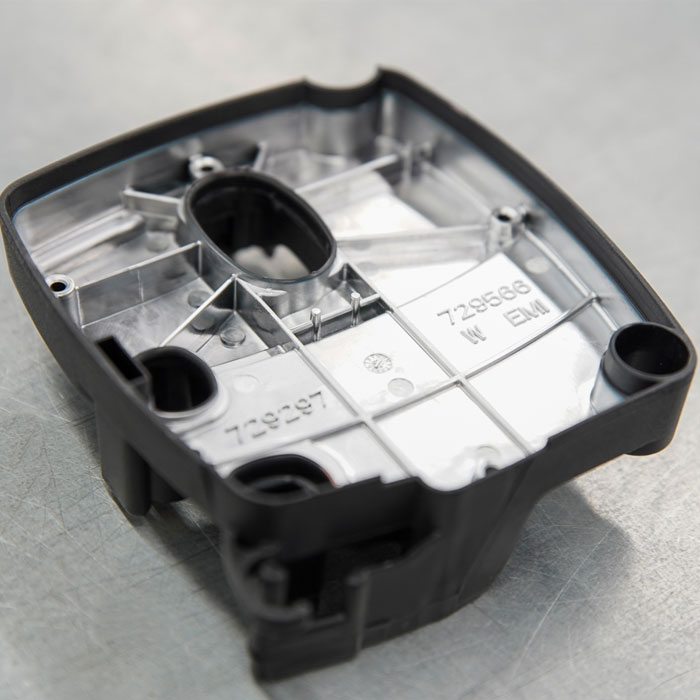

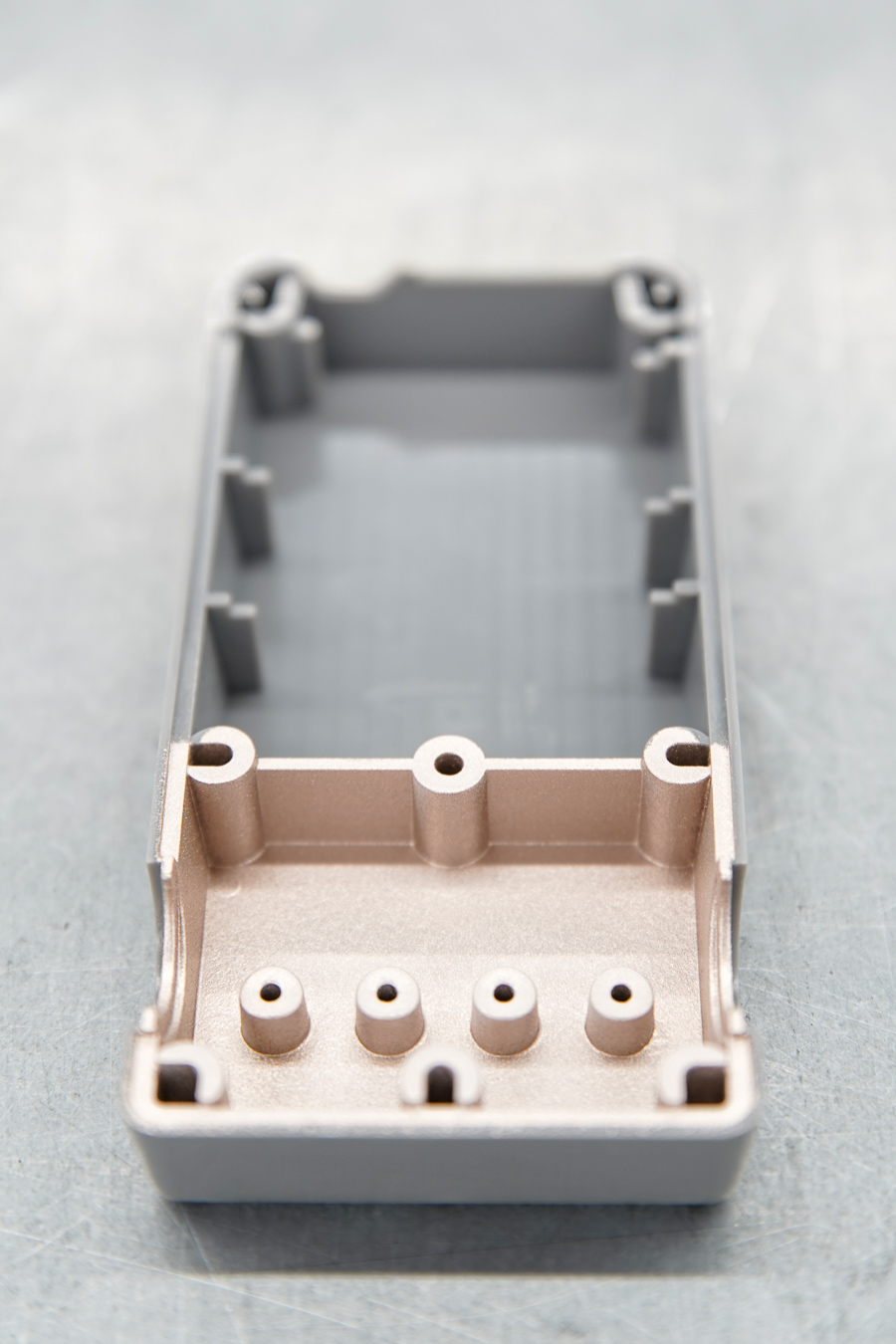

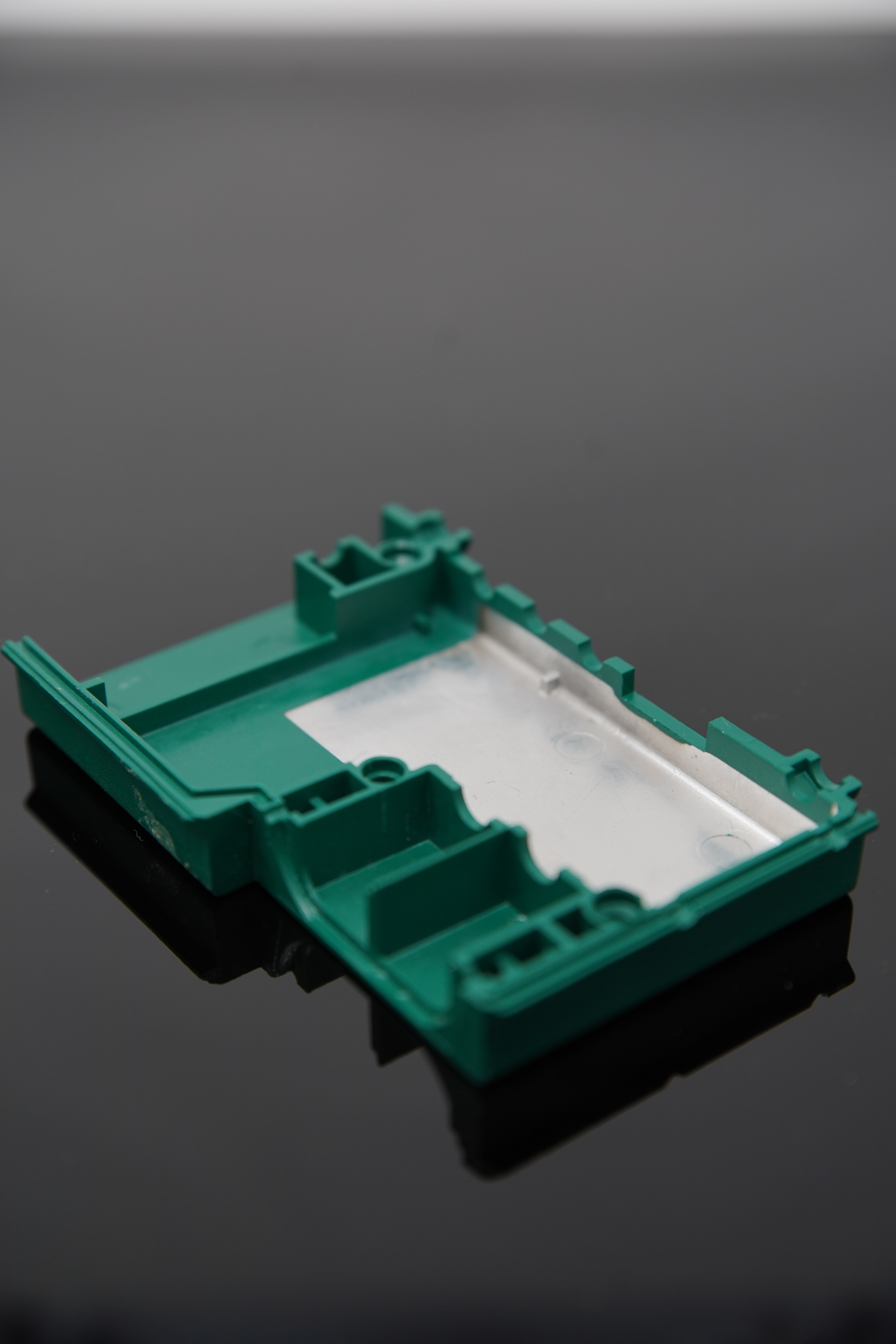

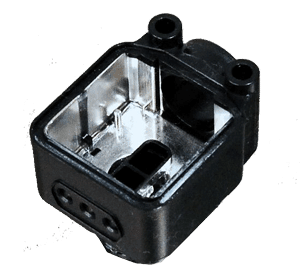

Mueller’s specialized coating processes provide interference protection for even the most challenging components. We offer thermal evaporation vacuum metalizing and PVD sputtering as well as conductive spray painting, providing a variety of shielding solutions, including:

Mueller’s specialized coating processes provide interference protection for even the most challenging components. We offer thermal evaporation vacuum metalizing and PVD sputtering as well as conductive spray painting, providing a variety of shielding solutions, including:

• EMI shielding (Electromagnetic Interference Shielding)

• RFI shielding (Radio Frequency Interference Shielding)

• ESD shielding (Electrostatic Discharge Shielding)

Our multiple pre-treatment processes ensure that all coatings have exceptional adhesion and remain free of flaking and peeling.