At Mueller Corporation we recognize the ever-changing fast-pace world of medical device manufacturing, and we are equipped to handle all of your needs. For over 60 years, Mueller has established a reputation for providing medical device manufacturers with quality coating solutions and services on a wide variety of applications. With an ISO 13485:2016 Certification, we are ready to meet all your medical device manufacturing needs.

At Mueller Corporation we recognize the ever-changing fast-pace world of medical device manufacturing, and we are equipped to handle all of your needs. For over 60 years, Mueller has established a reputation for providing medical device manufacturers with quality coating solutions and services on a wide variety of applications. With an ISO 13485:2016 Certification, we are ready to meet all your medical device manufacturing needs.

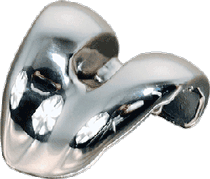

Our vacuum metalizing and spray coating services include:

- EMI/RFI shielding utilizing aluminum, copper, stainless steel, nickel chrome and conductive paint

- Decorative vacuum metalized and painted finishes

- Highly reflective coatings for light reflectors

- Functional coatings; PTFE coatings, heat shielding, vapor barriers, ceramic coatings (Cerakote) and more