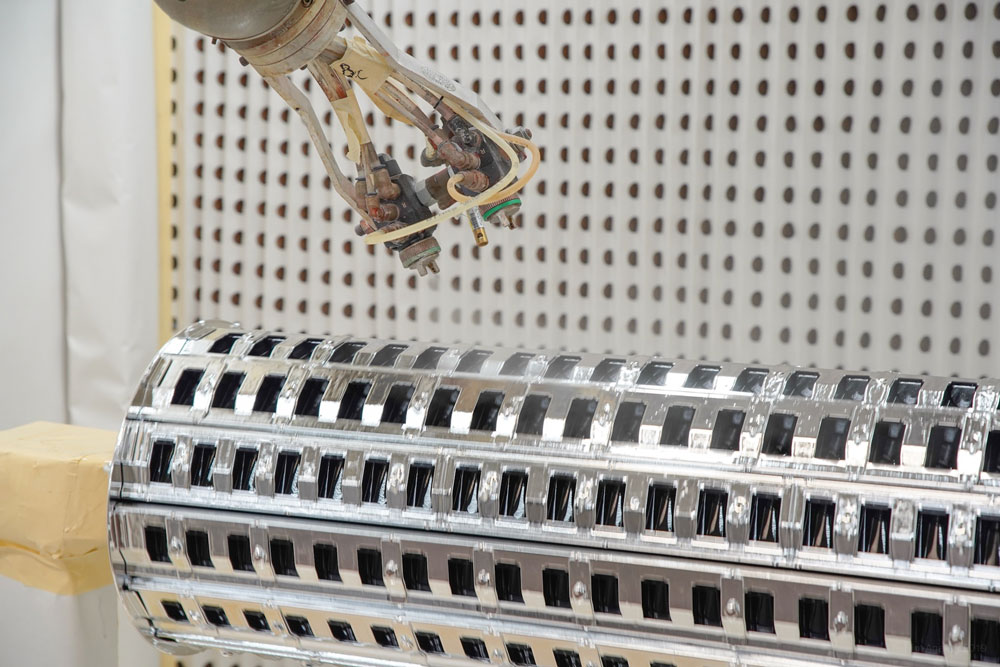

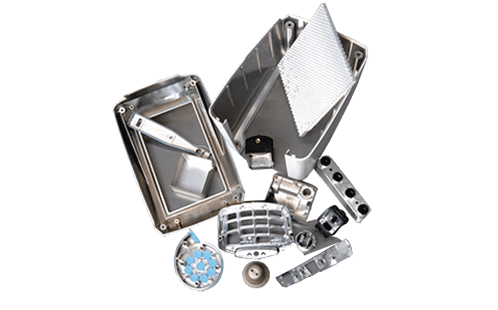

Mueller Corporation uses a combination of vacuum metalizing with a spray coated base and top coat to achieve the best results for our customers. Our vacuum metalizing process provides an even coating without large build ups, while our spray coatings provide an adhesive base and customizable functional and decorative top coats.

Mueller’s superior processes are executed by our team of engineering experts in our full capacity facility. To learn more about what makes Mueller the right choice for your next coating project, visit our Why Mueller page.