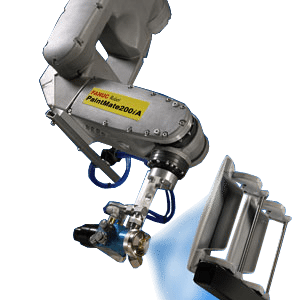

Since our founding in 1955, Mueller Corporation has been a leader in the delivery of reliable, scalable and cost-effective spray coating processes that meet a broad range of particular product finish and material properties. Our team of experts and full capacity facility allow us to deliver processes that meet demanding manufacturing cost, product quality, production scale and material property requirements.

We specialize in both functional and decorative spray coatings, which provide a wide range of results.

Functional spray coating applications:

- Conductive paint for EMI/RFI Shielding

- Ceramic coatings for corrosion and chemical protection

- Teflon (PTFE) coatings for low coefficient of friction abrasion and chemical protection

- Mil-Spec and Chemical Agent Resistant Coating (CARC) for military equipment.

Decorative spray coating applications:

- Soft touch or tactile

- Metallic finishes

- Gloss and satin clears

- A variety of gloss and satin colors