PRESS RELEASE

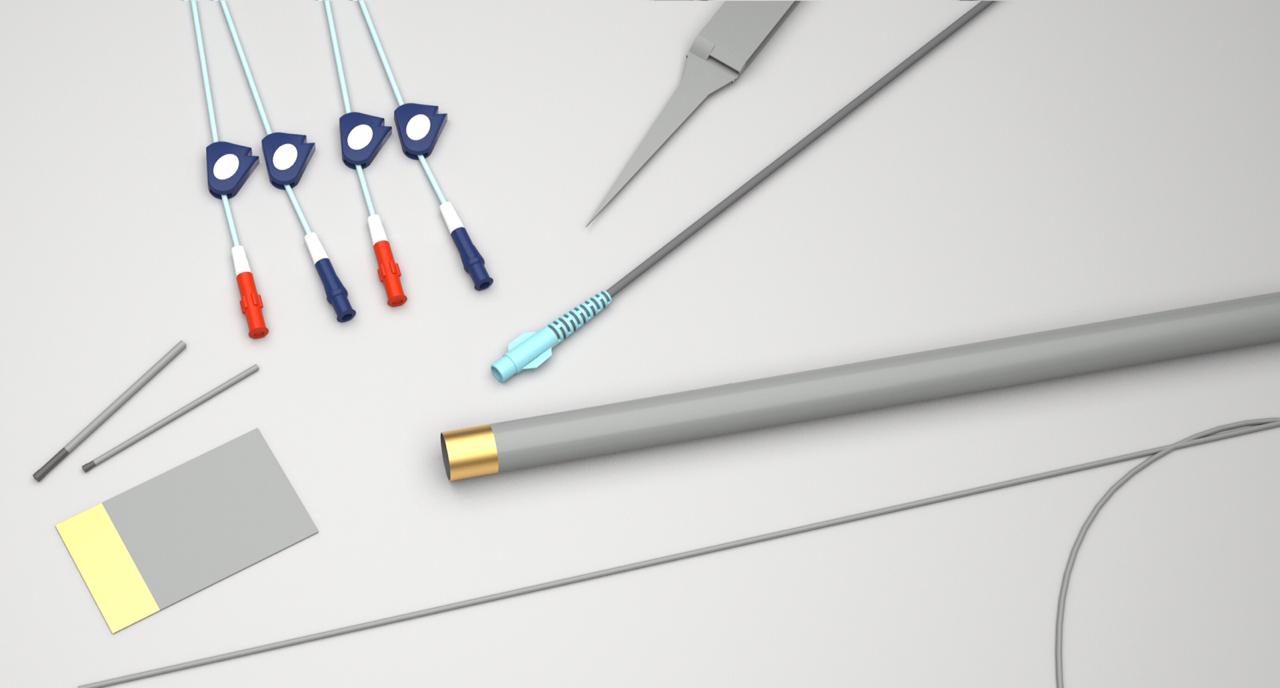

EAST BRIDGEWATER, MA – Mueller Corporation, a leader in the vacuum metalizing and functional coatings industry, announced recent updates to their suite of functional coatings to include PTFE, FEP, PFA, and fluoropolymer coatings. This updated suite of industrial coatings are widely used for projects pertaining to medical manufacturing, medical devices, and the aerospace and defense industries. With ISO 9001, ISO 13485, AS 9100, and ITAR certifications, Mueller Corporation is fully equipped to support clients with functional PTFE coatings for a variety of applications.

Polytetrafluoroethylene is a synthetic polymer consisting of carbon and fluorine. It is designed to withstand high temperatures, water, chemicals, and provide a low coefficient of friction. PTFE can be used in commercial applications of industrial coatings to optimize the quality and performance of medical products and aerospace/defense products.

Mueller’s new suite of fluoropolymer coatings includes:

- PTFE coatings

- ETFE coatings

- PFA coatings

- FEP coatings

- Primers and thinners

Our coatings experts are prepared to help you choose the appropriate industrial coating for your application, and our PTFE product & market guide is available upon request.

Mueller has more than 60 years of experience applying industrial coatings to Medical product components and military and aerospace products. With this added line of high-quality PTFE coatings and quality certifications, Mueller is proud to support some of the United States’ most respected companies with functional coatings for even the most intricate projects.

PTFE industrial coatings offer the following properties:

Nonstick: Very few solid substances will permanently adhere to a PTFE industrial coating. While tacky materials may show some adhesion, almost all substances release easily.

Low Coefficient of Friction: Friction is a force created when two objects rub together that hinders the motion. With PTFE industrial coatings, the coefficient of friction is generally lowered to a range of 0.05 to 0.20, depending on the load, sliding speed, and type of coating used.

Heat Resistance: PTFE industrial coatings can operate continuously at temperatures up to 500°F, and can be used for intermittent service up to 550°F with adequate ventilation without affecting any other properties.

Cryogenic Stability: Many PTFE industrial coatings can withstand temperatures as low as -454 ° F without loss of physical properties or affecting any other properties.

Chemical Resistance: Chemical environments usually do not affect PTFE industrial coatings. The only chemicals known to affect these coatings are molten alkali metals and highly reactive fluorinating agents. The coatings’ low porosity leads to great permeation resistance.

Non-Wetting: PTFE industrial coatings are both hydrophobic and oleophobic. The low surface energy of the coatings means that the cohesive forces in the water are strong enough to make the water bead up and not spread across the surface of the coating.

Unique Electrical Properties: Over a wide range of frequencies, PTFE industrial coatings have a high dielectric strength, low dissipation factor, and high surface resistivity. Adding fillers to certain coatings can make them electro-conductive enough to be used as an anti-static coating.

Abrasion Resistance: PTFE industrial coatings are very resistant to scratches and abrasion due to their excellent durability and toughness. Surface scarring is minimal, especially in certain coatings with property enhancing fillers.