At Mueller Corporation, we recognize the ever-changing, fast-paced world of the medical device industry, especially during the Covid-19 pandemic and its effect on the medical and healthcare systems, and we are equipped and ready to handle all your medical device manufacturing needs. From ventilator parts to medical testing devices and everything in between, Mueller Corp. is working with molders and contract manufacturers around the clock to provide PVD coatings for medical devices.

We pride ourselves on our ability to deliver processes and implement rigorous in-process systems and cross checks to ensure we are delivering exceptional, ISO-certified results for our customers on every project. We are also proud to provide Physical Vapor Deposition for leaders in the medical manufacturing industry, like Johnson & Johnson, Abbott Labs, Thermo Fischer Scientific, Merz, Olympus, Varian Medical Systems, and Nypro.

Our team members are skilled in all our vacuum metalizing and spray coating applications, including:

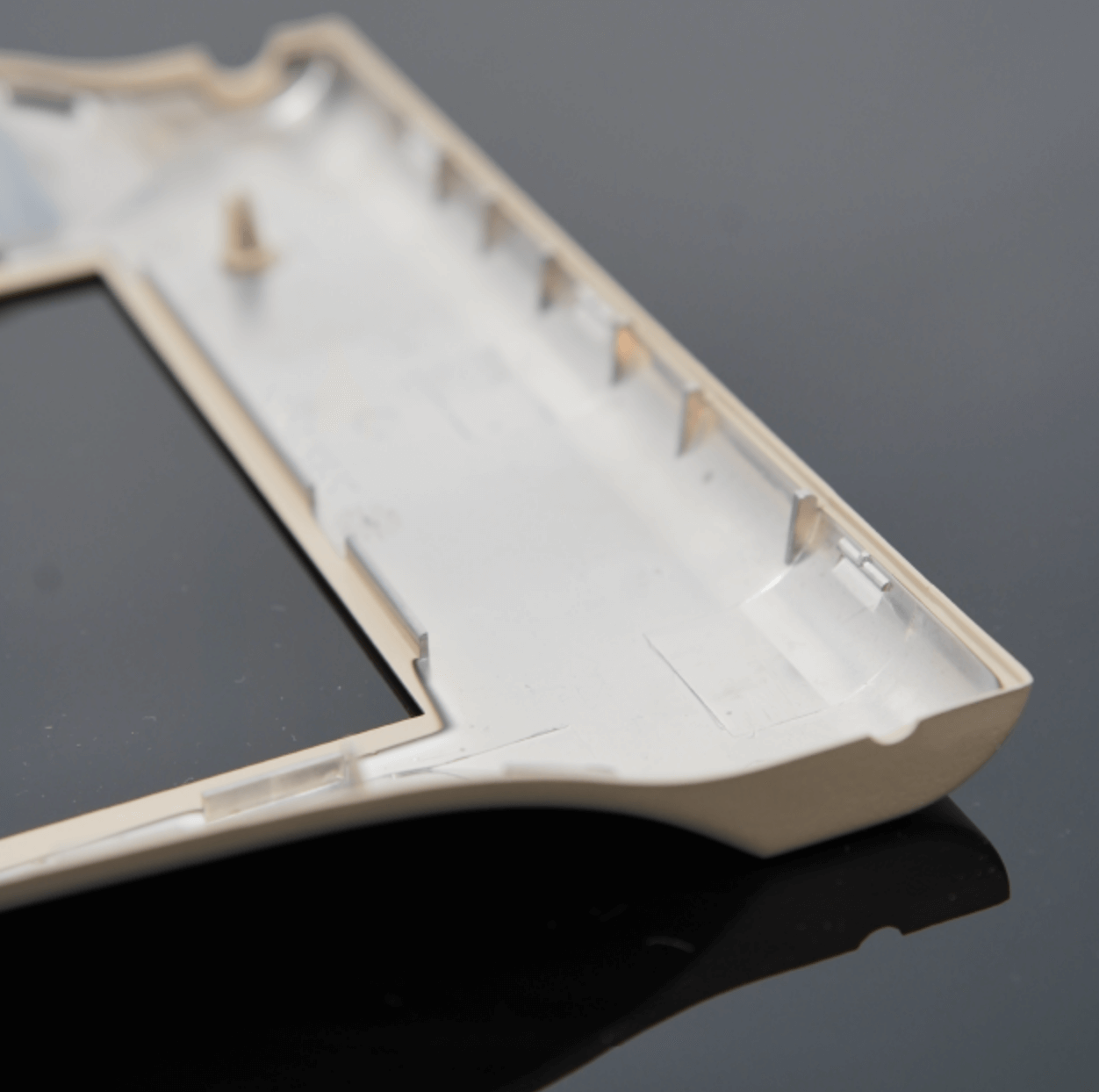

- EMI/RFI shielding

- Physical Vapor Deposition (PVD) coatings, or Aluminum Vapor Deposition (AVD) Coatings

- Decorative vacuum metalizing and painting

- Heat shielding

- Highly reflective coatings

- Vapor barriers

- Ceramic coatings

- Teflon coatings

We are equipped to be your full-capacity, turnkey supplier. Mueller invests significant resources, both in staff training and equipment, to ensure that our processes deliver optimal results. We operate 24 hours a day 7 days a week in a climate controlled 50,000-square-foot facility which is one of the largest in the industry. This allows us to provide our customers with fast turnaround times, small batch to high volume capacity, and precise coating results.

In addition to our specialty solutions used in the medical device industry, Mueller offers a wide range of other functional, decorative, and reflective finishes.

We offer vacuum metalizing and spray coating services for many functional applications, including:

- Metalized vapor barriers to protect against moisture, gas, and air

- Reflective heat shielding and insulation metalized and spray coatings

- Teflon spray coatings for low coefficient of friction / anti-stick

- Ceramic spray coatings for chemical and abrasion resistance and the ability to withstand high temperature environment

- CARC (chemical agent resistant coatings) coatings

Mueller Corporation achieves a variety of decorative results using both metalizing and spray coating processes. We can deliver many beautiful decorative finishes, including gold, bronze, copper, or chrome in bright or satin, colored or black chromes, gunmetal, and anodized looks. Our proprietary processes allow us to apply attractive finishes to almost any substrate, creating durable and flexible decorative results such as metallic finishes, tactile coatings, matte finishes; high-gloss and candy colors, and textured finishes.