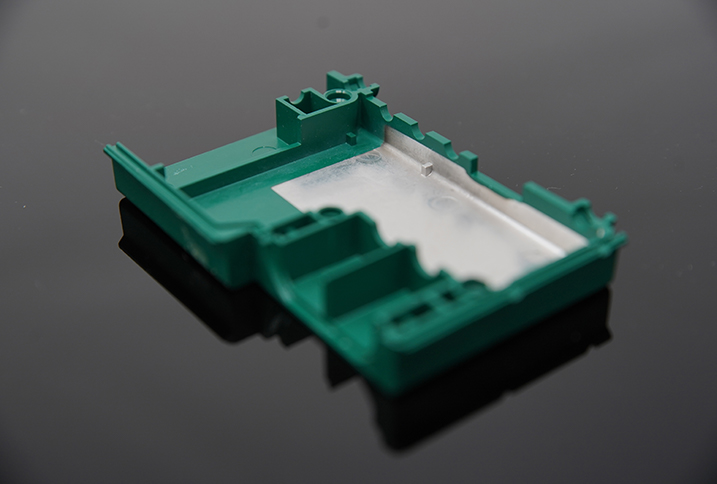

Electronic devices are made of a variety of materials including both metals and plastics. Most of today’s technology requires EMI (electromagnetic interference) or RFI (radio frequency interference) shielding in order to function properly and avoid interference or signal loss. These shields can be made of metal or can come in the form of a metal coating on plastic.

One of the easiest ways to add EMI or RFI shielding to your electronic devices is by coating the plastic parts of the device. This process allows for optimal performance and can ensure that signal isn’t lost due to interference from the outside or signal loss coming from the device itself.

Here are 3 reasons the plastic parts of an electronic device may need EMI shielding:

1) Signals

When you have a device that emits a signal, such as a cell phone, it’s vital to ensure that the signal flows outward the way it needs to flow. EMI shielding can ensure that the signal flows correctly and has an easy time reaching its destination.

2) Multiple Device Parts

Today’s modern technology features tons of electronic parts, all working independent of one another as well as working together. Many different parts of an individual electronic device may need to send a signal from one place to another. Unfortunately, too many uncontrolled signals can cause interference, causing communication and functional errors. With proper EMI shielding, every part of the device can deliver its signals correctly.

3) Outside Interference

If a device comes in close contact with another device, it will likely have trouble dealing with the interfering signals. EMI shielding removes this problem, limiting the pathways for the foreign signals to enter. That way, the device can work properly even in the presence of many others.

Coating plastic parts with EMI or RFI shielding metals offers many different benefits. It can be less expensive to coat plastic parts compared to installing metal pieces within a device. It can also be easier to coat the plastic pieces with many layers of various metals compared to manufacturing pieces made of a variety of metals. Coating plastic parts can also help limit the amount of space needed for shielding within a device, driving down the overall size of the product.

Plastic components may need EMI or RFI shielding in order to function properly and avoid interference from other devices. Adding the right coating can make all the difference in the functionality of the product. Be sure to add the right coating to your plastic parts to ensure your devices work well.

About Mueller Corporation

Founded in 1955, Mueller Corporation offers customers a diversity of vacuum metalized and industrial coatings to satisfy any decorative or functional finishing needs. Mueller Corporation maintains the highest customer satisfaction and quality assurance by continuously investing in its products and its people. With an emphasis on developing innovative coatings through research and development and continual improvement of our process through emerging technologies and applications, Mueller Corporation remains the leader in functional and decorative coatings for brands across the globe.