What is EMI Shielding?

EMI shielding is the process of reducing the electromagnetic field around a device as much as possible to help keep it functioning. This is done by adding physical barriers that can block outside signals from entering the device.

Electronic devices can perform amazing tasks that can’t be done by any other means. However, they do have their limitations. One of the biggest issues with electronic devices is interference.

In order for a device to work properly, the signals flowing through it need to be able to reach their destination without a problem. If other electronic devices are operating nearby, interference can become a problem, unless an EMI shield is present.

How does EMI Shielding Work?

The amount of shielding required depends on the device and its surroundings. Computer parts, for example, are very close together and require powerful shielding in order to avoid interfering with one another.

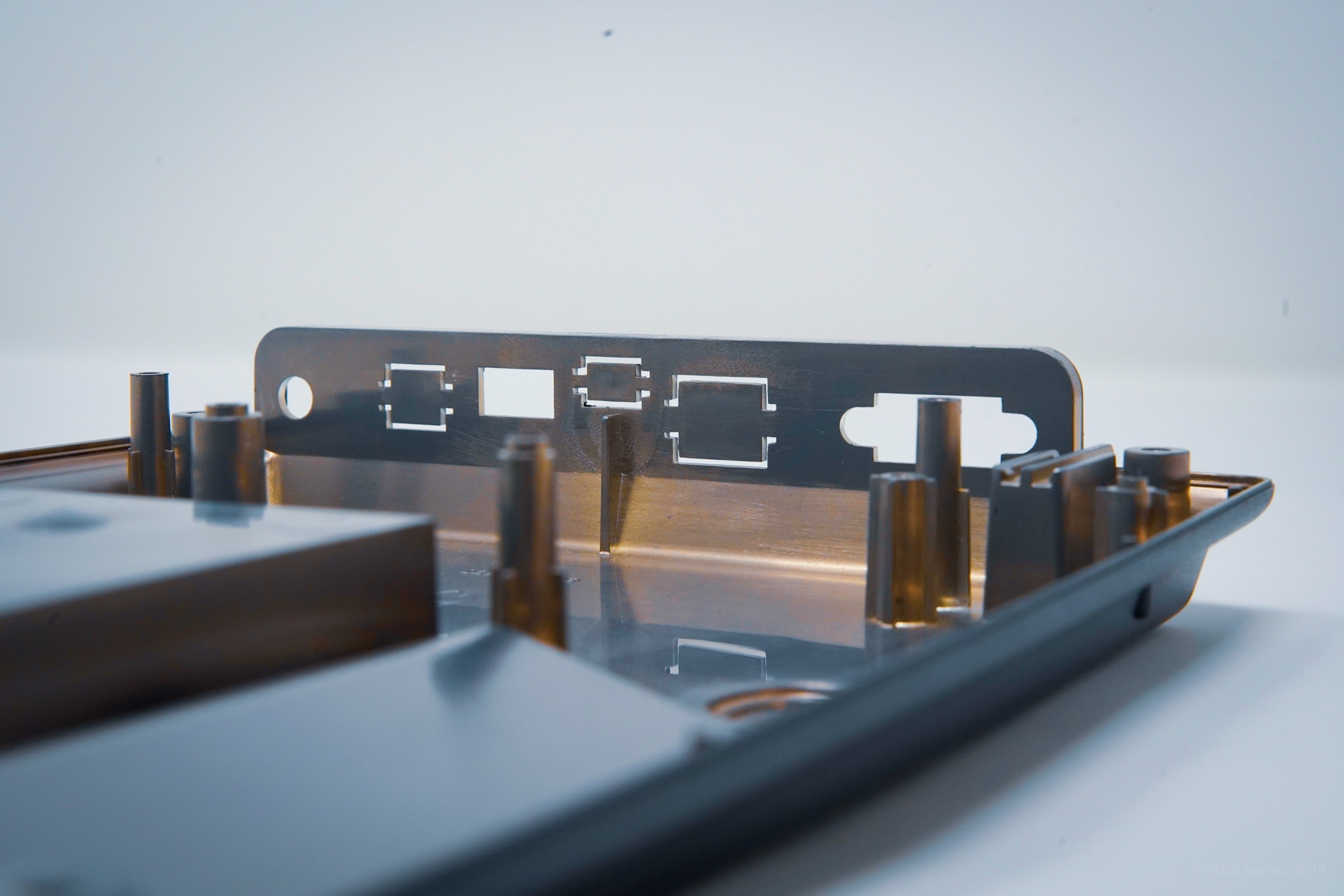

The level of shielding provided by the physical barrier is based on a number of factors. These include the metal thickness, materials, openings, and the frequencies being emitted inside and outside the device.

Metals like tin, silver, nickel, and steel are commonly used for EMI shielding. The metal’s conductivity, permeability, and other properties play a big role in their usefulness as EMI shielding. Depending on the type of device, certain metals are perfect for blocking interference while others are more likely to cause it. For example, copper is used for RF shielding because the metal can absorb radio waves.

EMI shielding is a vital part of most electronic devices for a number of reasons. In the most basic terms, without the right shielding, signals can’t be effectively delivered from one part of the device to another.

Coax cables are a great example of the usefulness of EMI shielding. These collections of copper wire deliver video signals from an access point to a screen. They are wrapped in a protective coating and EMI shielding, ensuring the signal is not lost along the way. Without this shielding, the images produced would be of much lower quality.

To Conclude

Equipping your parts with the right EMI shielding can be the difference between fully functional devices and devices that fail to deliver. Be sure to add the right shielding to your parts before going to market with your product. If you have more questions about EMI shielding, be sure to contact the experts at Mueller Corporation. Our team specializes in EMI shielding and vacuum metallization processes. Using the right metals and techniques, your devices and parts can feature the best shielding to ensure proper function.

About Mueller Corporation

Founded in 1955, Mueller Corporation offers customers a diversity of vacuum metalized and industrial coatings to satisfy any decorative or functional finishing needs. Mueller Corporation maintains the highest customer satisfaction and quality assurance by continuously investing in its products and its people. With an emphasis on developing innovative coatings through research and development and continual improvement of our process through emerging technologies and applications, Mueller Corporation remains the leader in functional and decorative coatings for brands across the globe.